Stainless steel etching refers to a specialized metal etching process that uses corrosive chemicals to etch complex shapes from sheets of stainless steel. The process of stainless steel etching is a highly accurate process that results in more complex parts with no mechanical stress placed on the material. Read More…

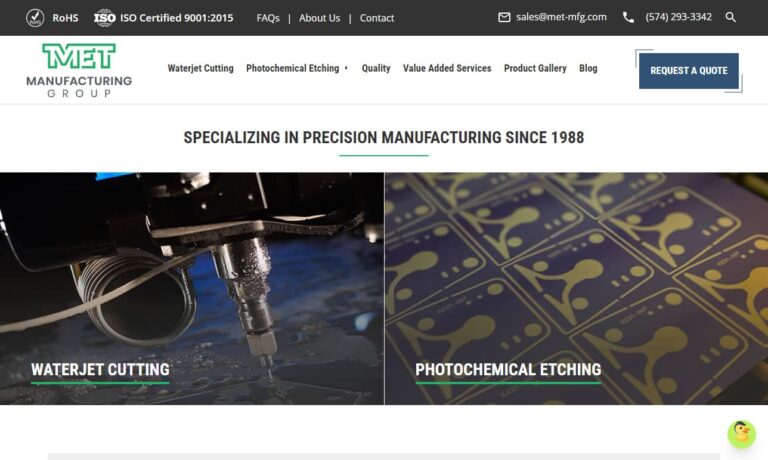

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

More Stainless Steel Etching Companies

Stainless Steel Etching: Process, Applications, and How to Choose a Supplier

Stainless steel etching is a precision metal processing technique widely used for manufacturing high-quality, intricate components. Due to its outstanding properties—such as corrosion resistance, strength, and a smooth, tarnish-free finish—stainless steel is an ideal material for a range of etching methods including laser etching, chemical etching, photochemical etching, and electrolytic etching. These advanced processes are essential for industries requiring detailed, burr-free parts with tight tolerances and minimal mechanical stress. If you’re looking to improve product quality or explore rapid prototyping options, understanding the fundamentals and applications of stainless steel etching is critical for informed purchasing decisions.

Wondering how to select the right stainless steel etching process for your project, or how to evaluate suppliers? Read on for an in-depth guide covering process types, industry applications, benefits, and key factors when choosing a stainless steel etching company.

Why Stainless Steel Is Ideal for Etching

Stainless steel is an excellent substrate for etching techniques due to its unique combination of durability, formability, and resistance to corrosion and heat. Etched stainless steel parts can achieve exceptional photo quality and intricate detailing, making them suitable for both functional and decorative applications. The material’s compatibility with photo-resistant laminate masks and computer-aided design (CAD) images further streamlines the photochemical etching process, ensuring precise reproduction of complex patterns.

One notable advantage of stainless steel etching is that, unlike mechanical cutting or stamping, the process does not introduce stress or burrs to the metal. This ensures components maintain their integrity, mechanical properties, and dimensional accuracy—critical for high-performance applications in aerospace, automotive, electronics, and medical device manufacturing.

Grinding and milling machines are occasionally used to achieve specific etched finishes on stainless steel sheets, especially for architectural or larger decorative panels. However, when precision, repeatability, and fine detail are required, chemical and photochemical etching processes are preferred by industry professionals.

How Does Stainless Steel Etching Work?

The etching process typically starts with the stainless steel sheet being laminated with a light-sensitive photoresist. A CAD image of the desired component is then transferred onto the metal by exposing the photoresist to ultraviolet (UV) light. Areas of unexposed photoresist are removed, leaving behind a pattern that accurately mirrors the design blueprint. The exposed areas are then subjected to an etchant—such as ferric chloride, nitric acid, or other specialized chemicals—which selectively removes unwanted metal. After etching, the remaining photoresist is stripped away, revealing a sharply defined, precisely etched component.

This method enables the mass production of highly intricate and accurate parts, all while preserving the mechanical properties of the base stainless steel. The absence of burrs or heat-affected zones makes etched stainless steel components highly desirable for industries where performance and reliability are non-negotiable.

Types of Stainless Steel Etching Processes

The optimal stainless steel etching process depends on application requirements, production volume, and desired features. The three most common etching techniques are laser etching, chemical etching, and electrolytic (electrochemical) etching. Each method uses a different approach to selectively remove metal from the substrate, and each offers unique advantages for specific use cases.

- Laser Etching—uses focused, high-energy laser light to vaporize or melt away metal at precise locations

- Chemical Etching—employs acidic chemical solutions to dissolve exposed areas on the metal surface

- Electrolytic Etching—applies an electrical current through a chemical electrolyte to transfer ions and etch the metal

- Photochemical Etching—combines photoresist masking and chemical etching for extremely fine, detailed patterns

Laser Etching Stainless Steel

Laser etching employs a focused, high-density laser beam to engrave or mark stainless steel surfaces. This non-contact process offers exceptional speed, flexibility, and precision—making it highly suitable for serial numbers, barcodes, logos, and intricate patterns. The laser targets the metal surface, with some light reflecting off but the majority absorbed as heat. This intense, localized heating melts or vaporizes the metal, producing a clean, permanent mark.

Are you interested in fast, high-contrast markings for ID tags, traceability, or branding? Laser etching is frequently used for:

- Industrial component marking

- Medical device identification (compliant with UDI regulations)

- Automotive parts serialization

- Consumer product labeling

- Decorative engraving for architectural and consumer goods

Laser etching offers advantages such as no need for consumables, rapid setup, and the ability to etch variable data on-the-fly. If you need high-speed, contactless, and durable marking, laser etching is often the top choice.

Electrolytic (Electrochemical) Etching

Electrolytic etching—sometimes referred to as electrochemical etching—relies on an electric current to transfer ions between an anode and cathode through a conductive electrolyte. The part to be etched is connected to the positive terminal (anode) of a DC power source, while a cathode is connected to the negative terminal. When power is applied, ions migrate from the anode (the component) to the cathode, selectively removing material from the surface and creating a permanent, high-contrast etch.

This process is especially effective for batch marking, serialization, and logo application on stainless steel parts. It is commonly used in industries where traceability and product identification are crucial, such as aerospace, medical, and industrial manufacturing.

- Permanent, tamper-proof markings

- Low operational costs

- Minimal thermal distortion or mechanical stress

- Ideal for stainless steel tools, blades, and surgical instruments

Chemical Etching

Chemical etching (also called acid etching or chemical milling) uses corrosive chemicals—typically ferric chloride, hydrochloric acid, nitric acid, or sulfuric acid—to dissolve unprotected areas of stainless steel. The process begins by applying a maskant or photoresist to areas that need to remain untouched. The metal is then immersed in an acid bath or exposed to a flow of etchant, which removes material in the pattern defined by the mask.

Looking to manufacture high-precision, burr-free stainless steel components at scale? Chemical etching is ideal for:

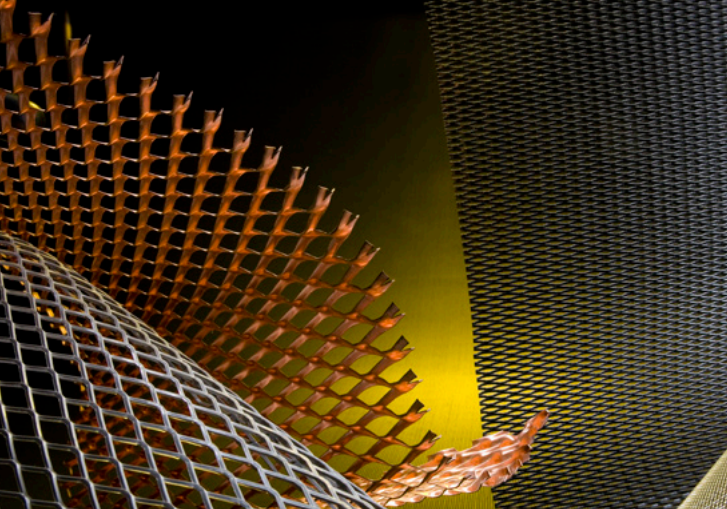

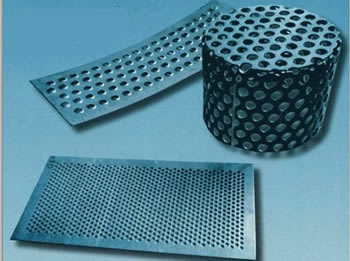

- Complex parts with fine features, such as filters, meshes, and screens

- Thin metal parts for electronics, automotive, and aerospace

- Rapid prototyping and low-to-medium volume production

- Parts requiring no heat-affected zone or mechanical deformation

Chemical etching is valued for its scalability, low tooling costs, and ability to handle intricate geometries that are difficult or impossible with mechanical machining. It is also a preferred method for producing stainless steel nameplates, precision shims, gaskets, and EMI/RFI shielding components.

Photochemical Etching

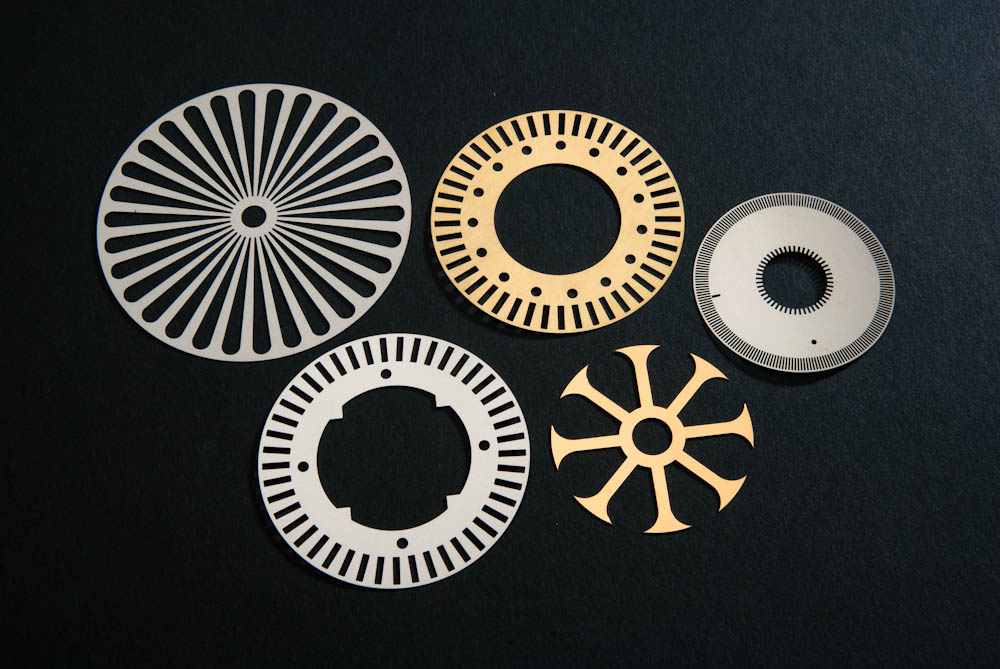

Photochemical etching is an advanced form of chemical etching that uses a photoresist applied to the stainless steel surface, combined with a UV-exposed CAD image to create highly detailed, repeatable patterns. This process is particularly suitable for high-precision, thin-gauge metal components and is favored in electronics, MEMS, and microfluidics manufacturing.

Photochemical etching allows for:

- Ultra-fine features with micron-level accuracy

- Rapid turnaround and prototyping

- Mass production of intricate parts with minimal tooling changes

- Low setup costs for design changes or small production runs

If your project demands tight tolerances, complex geometries, or frequent design modifications, photochemical etching is a cost-effective and flexible solution.

What Are the Key Applications of Stainless Steel Etching?

Stainless steel etching is foundational to industries requiring precision, performance, and aesthetics. The most common applications include:

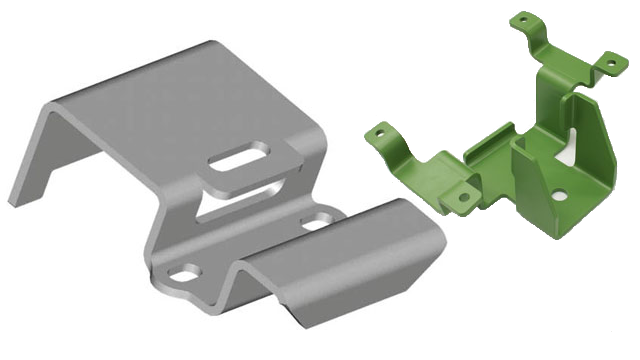

- Aerospace and Automotive: Engine components such as fuel cell plates, shims, gaskets, and heat shields demand high strength, corrosion resistance, and accuracy.

- Medical Devices: Surgical instruments, implantable devices, and diagnostic equipment benefit from burr-free, clean surfaces that withstand repeated sterilization.

- Electronics: EMI/RFI shielding, lead frames, springs, and connectors require fine features and dimensional stability.

- Industrial Equipment: Filters, screens, and custom machine parts rely on precise, repeatable etching for optimal function.

- Consumer Goods: Decorative panels, jewelry, plaques, trophies, and musical instruments utilize stainless steel etching for intricate, durable designs.

- Architectural and Interior Design: Decorative sheeting, signage, and branded elements leverage laser and chemical etching for visual impact and longevity.

Need a specific stainless steel part etched for your next project? Contact a chemical etching company to discuss your requirements and receive expert recommendations.

Benefits of Stainless Steel Etching

Why choose stainless steel etching over mechanical machining, stamping, or laser cutting? The advantages are extensive, including:

- Burr-Free Components: No mechanical cutting means smooth edges without secondary finishing.

- No Thermal or Mechanical Stress: Maintains material properties, essential for critical applications.

- High Precision and Repeatability: Achieve tight tolerances and consistent quality, even for complex designs.

- Design Flexibility: Easy to modify designs and produce small or large batches cost-effectively.

- Material Versatility: Compatible with various stainless steel grades, including 304, 316, and others.

- Surface Quality: Produces clean, smooth, and easily sanitized surfaces—ideal for medical and food-grade applications.

- Scalability: Efficient for prototypes, low-volume production, and mass manufacturing.

- Cost-Effective Tooling: Lower upfront costs for complex or frequently changing designs.

Curious about how stainless steel etching can benefit your manufacturing process? Compare it with alternative metal fabrication techniques to find the best fit for your needs.

Factors to Consider When Choosing a Stainless Steel Etching Company

When selecting a stainless steel etching supplier, it’s critical to evaluate several factors to ensure optimal quality, service, and cost-effectiveness. Here’s a checklist to guide your decision:

- Technical Capabilities: Can the supplier handle your required part sizes, thicknesses, tolerances, and production volumes?

- Experience and Industry Expertise: Look for suppliers with proven track records in your sector—such as aerospace, medical, or electronics.

- Certifications and Compliance: Does the company meet quality standards like ISO 9001, AS9100, or medical device regulations?

- Material Selection: Can they process your preferred stainless steel grades (e.g., 304, 316, 430)?

- Design Support: Do they offer CAD design assistance, prototyping, or engineering support?

- Turnaround Time: Ask about lead times for prototypes, production runs, and design changes.

- Cost Transparency: Request detailed quotes and understand the cost drivers, including tooling, setup, and batch sizes.

- Customer Service: Is communication prompt and clear? Do they provide technical guidance and after-sales support?

- Value-Added Services: Inquire about post-processing options such as plating, passivation, finishing, or assembly.

Want to find the best stainless steel etching supplier for your project? Consider the following actionable steps:

- Identify your application requirements—dimensions, tolerances, volume, and regulatory needs.

- Research suppliers with expertise in your industry and process type.

- Compare at least 4 suppliers using a dedicated supplier directory for stainless steel etching.

- Review each supplier’s business profile, capabilities, and areas of specialization.

- Use available contact forms or RFQ tools to request quotes and technical information.

- Evaluate responses for technical fit, lead time, pricing, and customer service.

- Request samples or case studies to assess quality and process reliability.

Each Stainless Steel Etching Company typically has a business profile page outlining their experience, certifications, and technical capabilities. Use patented website preview tools, if available, to quickly assess their specialties, and then leverage RFQ forms to efficiently contact multiple suppliers for competitive quotes.

Frequently Asked Questions About Stainless Steel Etching

What stainless steel grades are best for etching?

Most etching processes work well with common stainless steel grades such as 304, 316, 301, 430, and 17-7PH. The choice depends on your application's requirements for corrosion resistance, strength, and thermal performance. Discuss your needs with your etching supplier to select the optimal grade.

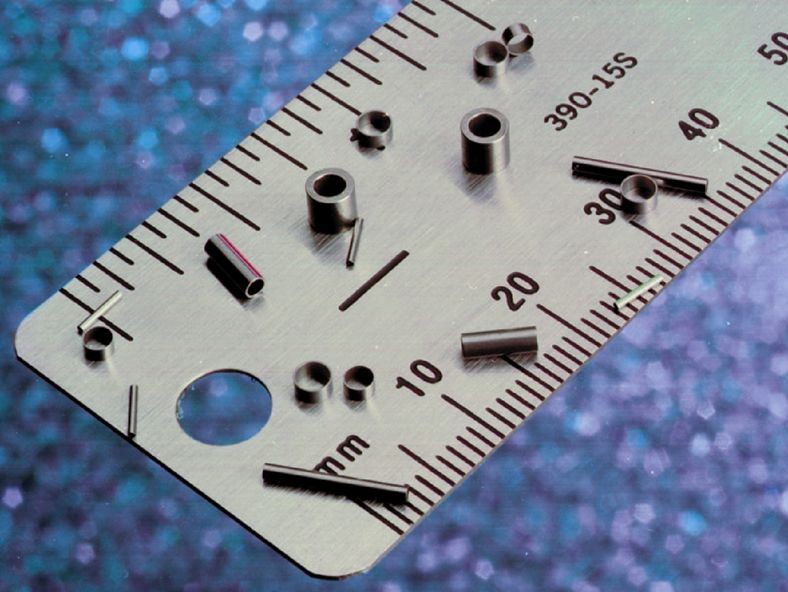

What is the minimum feature size achievable in stainless steel etching?

Photochemical and chemical etching processes can achieve feature sizes as small as 25 microns, depending on metal thickness and process control. Laser etching is also capable of fine detail but is typically used for marking rather than through-etching.

How can I ensure the quality of etched stainless steel components?

Partner with suppliers who provide rigorous quality control, including dimensional inspection, visual checks, and, if required, material certification and traceability. Request samples or first-article inspections for critical parts.

Is stainless steel etching environmentally friendly?

Modern etching facilities often incorporate closed-loop chemical recycling, waste minimization, and energy-efficient processes. Ask your supplier about their environmental practices and certifications for sustainable manufacturing.

How does stainless steel etching compare to stamping or laser cutting?

Etching processes offer superior precision for fine features, no heat-affected zone, and the ability to produce complex geometries without expensive tooling. Stamping is cost-effective for very high volumes but can introduce burrs and stress, while laser cutting is ideal for thicker materials or rapid prototyping but may require post-processing for best edge quality.

Get Started: Request a Quote or Expert Consultation

Ready to source stainless steel etched components or have specific application questions? Connect with leading stainless steel etching companies to discuss your project, compare capabilities, and request detailed quotes. Whether you need rapid prototyping, small batches, or mass production, expert suppliers can help you navigate process selection, material choice, and design optimization for the best results.

Still evaluating your options? Bookmark this page or share it with your engineering team for a comprehensive resource on stainless steel etching processes, benefits, and industry applications.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services