Metal etching, or metal engraving, is a method of creating impressed designs, grooves or fine lines on metal parts and sheets. Metal etching services are used for a wide variety of decorative and industrial applications. Decorative etching applications include jewelry design, musical instrument decoration, firearm engraving, plaque and trophy decoration and engraving and architectural and furniture embellishments. Read More…

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

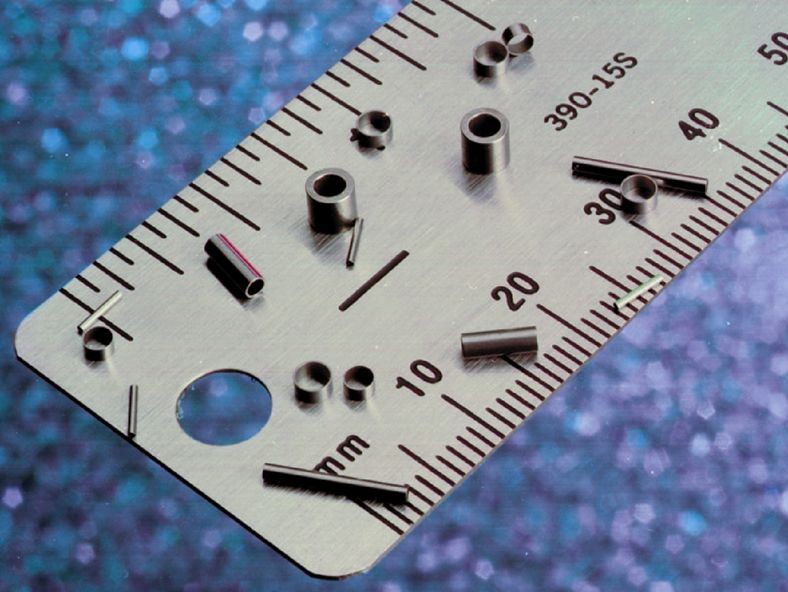

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

More Metal Etching Companies

In decorative metal etching, surfaces are occasionally smoked to enhance the visibility of etched lines and patterns. This age-old technique allows artisans and manufacturers to produce metalwork with striking visual clarity and intricate detail, making it a favored process for custom signage, jewelry, and architectural panels.

Industrial applications of metal etching and chemical etching span a wide range of sectors, including electronics, aerospace, automotive, defense, and the medical device industry. For example, metal photo etching is fundamental in producing stencils, nameplates, precision filters, and micro-components that demand high accuracy and repeatability. In the medical field, chemical machining and advanced etching techniques are utilized to achieve optimal finishes and complex geometries for devices such as stents, catheters, surgical blades, and implantable components. These medical devices require biocompatibility, burr-free surfaces, and tight tolerances, all of which are enabled by modern etching solutions.

Moreover, this versatile technique is essential for crafting intricate components and devices for the aerospace, electronics, and defense sectors. Metal etching plays a crucial role in fabricating printed circuit boards (PCBs), engraved missile skin panels, jet frames, fuel cell plates, RF shielding, and micro-electromechanical systems (MEMS). The ability to create complex geometries without introducing thermal or mechanical stress makes metal etching the process of choice for mission-critical applications where reliability and precision are paramount.

History of Metal Etching

The traditional method of metal etching involved manual labor using fine-tipped tools such as burins. While hand etching yielded unique, artistic patterns and textures, its labor-intensive nature and variability led to its gradual replacement by more efficient techniques like chemical etching and photochemical machining.

Etching, a technique known since the Middle Ages and possibly earlier, initially focused on soft metals like zinc and copper before advancing to stronger materials like steel. Notable medieval examples include ornate 16th-century armor, decorative cups, engraved plates, and firearms, many of which can still be found in museum collections today.

A pivotal moment in the history of metal etching occurred in the early 1500s when German craftsman Daniel Hopfer pioneered its application to printmaking. This process involved covering plates with acid-resistant wax, then using an etching needle to expose metal where desired. Subsequent immersion in acid dissolved exposed metal, leaving recessed lines used for printing. This method, known as intaglio printmaking, enabled the mass production of detailed images and contributed significantly to the spread of Renaissance art and literature.

Hopfer extended this method to embellish armor, evidenced by surviving pieces like a sword in the Germanisches National museum and a shield in the Real Armeria of Madrid. Although Hopfer’s direct involvement in all items is unclear, his influence is evident in surviving plates and artifacts.

Hopfer’s innovation supplanted traditional engraving methods, with metalworkers adapting chemical etching for trajectories on cannons, decorative items like shovels and daggers, and a wide variety of industrial and ornamental equipment. This marked the beginning of scalable, repeatable etching processes that would eventually evolve into today’s precision photochemical machining.

In the 18th century, Swiss botanist John Senebier’s observation of plant resin hardening under light spurred developments in photochemical etching and photography. Initial photo etching involved applying light-sensitive resin to metal, exposing it to light to create masked outlines, a technique crucial in producing metal plates for printing, electronics, and decorative arts.

Commercial adoption of photochemical machining began in 1927, pioneered by a Swedish company, Aktiebolaget Separator, for edge and gap filters. This method gained prominence during World War II for etching harder metals and producing intricate sheet foil parts from both sides—enabling the rapid manufacture of components for aircraft, radar, and communication equipment.

Since the mid-1900s, metal etching has evolved with advancements in maskants, etchants, CNC technology, and the incorporation of laser etching and electromagnetic discharges, enhancing precision and expanding applications. Today, metal etching is performed using digital design files, advanced photomasks, and environmentally friendly etchants, opening new possibilities in microfabrication, electronics, and rapid prototyping.

Metal Etching Materials and Processes

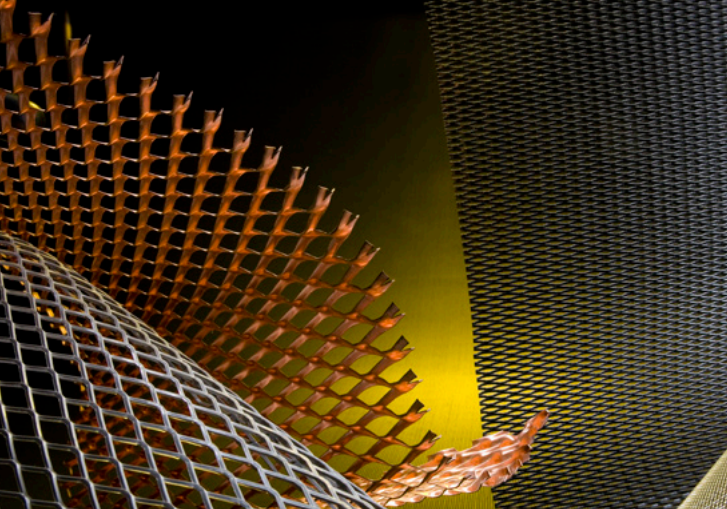

Commonly etched metals include aluminum, copper, stainless steel, nickel, and brass. Modern metal engraving machines can also process surfaces such as glass and plastic, expanding the range of products that benefit from precision etching.

Aluminum: Aluminum is a naturally occurring element known for its durability, softness, resistance to oxidation and corrosion, ductility, recyclability, and light weight. It is ideal for aerospace components, electronic housings, automotive trim, and signage due to its excellent strength-to-weight ratio and ease of etching. Aluminum etching is frequently used for creating EMI/RFI shielding, heat exchangers, and intricate decorative panels.

Copper: Found naturally in its metallic form, copper is valued for its softness, malleability, ductility, high thermal conductivity, and electrical conductivity. It is a crucial component in alloys like brass, nickel silver, and bronze due to its versatile properties. Copper etching is widely used in the production of printed circuit boards, electrical contacts, and battery components, where precise patterning and conductivity are essential.

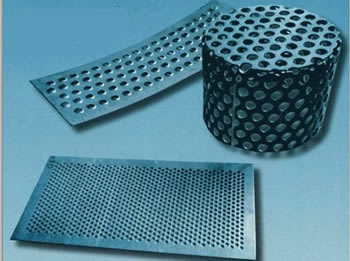

Stainless Steel: Composed of at least 10.5% chromium by mass, stainless steel is highly popular for its corrosion resistance, oxidation resistance, hypoallergenic properties, and exceptional strength and durability. Stainless steel etching is preferred for medical instruments, surgical tools, industrial filters, and decorative panels due to its clean, burr-free results and ability to maintain sharp features even in thin gauges.

Nickel: A transition metal symbolized by Ni, nickel is characterized by its ductility, hardness, luster, strength, and corrosion resistance. Nickel etching is commonly used in battery technology, micro-electromechanical systems (MEMS), fuel cells, and optical applications where precision and chemical stability are required.

Brass: Brass, a copper-zinc alloy, stands out for its high malleability, low melting point, castability, and antimicrobial properties against microorganisms and pathogens. Brass etching is often employed in nameplates, musical instruments, decorative hardware, and architectural elements to create visually appealing and functional products.

Metal Etching Process Details

Understanding the step-by-step metal etching process is crucial for ensuring high-quality results, whether your application is industrial, decorative, or electronic. Below is a detailed breakdown of the typical workflow:

1. Prepare the Surface

Begin by thoroughly cleaning the surface intended for etching using a deoxidizing or alkaline solvent solution. This step ensures the surface is free from contaminants such as oils, primer coatings, grease, and residue from metal markers. Removing these contaminants is crucial as they can interfere with chemical reactions, leading to inconsistent etching results and affecting the quality of the finished part.

2. Apply Maskant

Apply a masking agent to the workpiece in a predetermined pattern. Maskants can be applied by either immersing the parts in a solution (dip masking) or allowing the solution to flow over them (flow coating). Industrial maskants, often polymers or elastomers like isobutylene-isoprene copolymers or neoprene elastomers, are chosen for their ability to maintain structural integrity during chemical processes. Photolithographic techniques utilize photoresist coatings to create extremely precise and complex patterns, especially for microelectronics and medical devices.

3. Etch the Metal

Immerse the prepared metal into the etchant, such as ferric chloride, which initiates a corrosive reaction where unprotected areas of the metal are etched. The duration of immersion depends on the desired etching depth. Advanced etching lines may use automated conveyors and real-time monitoring to ensure uniform results across large production runs.

4. Remove the Masking Agent

After etching, remove the masking agent from the metal. Typically, this is done manually using scraping tools or with chemical solvents. To remove any remaining etchant, immerse the metal in a cold-water bath or a specialized deoxidizing solution. This step prevents unwanted reactions and ensures a clean, contamination-free surface.

5. Finishing Touches

Once etching is complete, manufacturers may further smooth or polish the metal to eliminate imperfections, burrs, or marks. Additional treatments, such as passivation, anodizing, or coating, may be applied to enhance corrosion resistance, surface appearance, or electrical insulation.

Design Considerations for Metal Etched Parts

When designing a metal etched part, manufacturers meticulously plan aspects such as the depth of cuts, etch patterns, minimum feature size, and overall geometry. Achieving the desired outcome involves careful consideration of several factors:

- Selecting the appropriate material for the application and end-use environment

- Determining the optimal etchant composition and concentration for the chosen metal

- Calculating the rate of etching (the ratio of cut depth to time in the bath) for precise control

- Deciding on the duration the metal will remain submerged, especially for deep or complex etches

- Controlling the temperature, agitation, and flow of etchant to ensure uniform results

- Managing tolerances, edge definition, and minimum/maximum feature sizes for critical components

- Ensuring compliance with industry standards (such as ISO 13485, AS9100, or IPC for electronics)

Commonly used etchants include ferric nitrate, ferric chloride (ideal for copper or zinc), nitric acid (preferred for zinc or steel), copper sulfate, HNO3, hydrochloric acid, and citric acid. Manufacturers typically conduct test runs or simulations to ensure precise execution and repeatability.

Machinery and Equipment Used in Metal Etching

Modern metal etching machinery is designed for both high-volume manufacturing and custom, low-volume prototyping, offering flexibility for a wide range of industries and applications.

Precision Machining with Lathe and CNC Controls

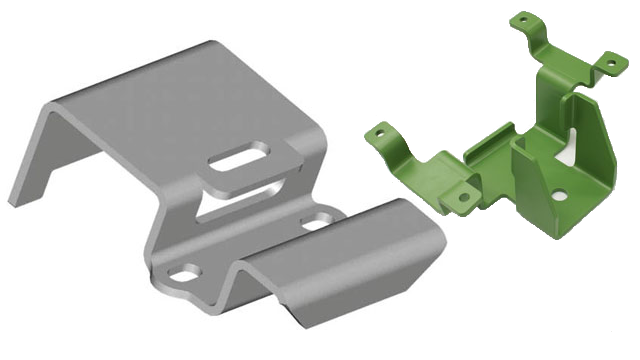

Mechanical milling employs either a lathe or CNC machine equipped with fine tips capable of processing various materials and dimensions, including straight or curved surfaces. Controlled by computer systems, these machines manage the cutter’s direction, pressure, and speed, ensuring the creation of precise, repeatable designs with clean, fine details. This is especially valuable for complex parts in aerospace, automotive, and electronics manufacturing where consistency and speed are essential.

Milling and Grinding Machines

Milling and grinding machines can achieve specific finishes on large metal sheets used in applications such as decoration, architectural panels, or high-end furniture. While these methods consistently deliver high-quality results, they incur high initial tooling costs and require maintenance by skilled personnel. Milling is ideal for applications where dimensional accuracy and surface finish are crucial, such as in precision dies and molds.

Hand Engraving Equipment

For smaller and more intricate projects, particularly decorative applications or prototyping, some manufacturers still utilize hand engraving equipment. This equipment typically consists of three main components: a stylus or marking tool, a controller, and a work surface. Styluses are often diamond-tipped to engrave even the hardest metals, enabling the creation of unique, bespoke designs for jewelry, awards, and commemorative items.

Variations and Similar Processes

There are several specialized techniques and related processes within the broader field of metal etching, each suited to specific applications and requirements:

Chemical Milling

Chemical milling, also known as photochemical milling or chemical machining, involves the use of a masking compound and an etchant. In this process, a sheet of metal is first coated with an inert masking compound. The metal is then immersed in a suitable etchant, which selectively dissolves the exposed areas. This method is ideal for producing lightweight aerospace components, intricate filters, and thin-walled parts with complex shapes.

Mechanical Milling

Mechanical milling is employed to etch various metal surfaces, both flat and curved. Controlled by CNC systems, the cutter or laser moves precisely at prescribed speeds, applying accurate pressure to create designs and patterns with clean, fine lines. The primary drawback of mechanical milling lies in its high initial tooling costs and the requirement for skilled maintenance personnel. This method is often chosen for applications where depth control is critical, such as embossing dies and forming tools.

Acid Etching

Similar to chemical milling, acid etching involves using maskants such as tape, paint, rubber elastomers, or plastics. These maskants are applied in the desired pattern on the metal surface. Acid, known as the reagent, is then applied to the exposed areas. After processing, the maskants and reagents are removed, revealing the final etched part. Acid etching is commonly used to produce images, lines, grooves, and perforated surfaces on metals such as copper, brass, and steel.

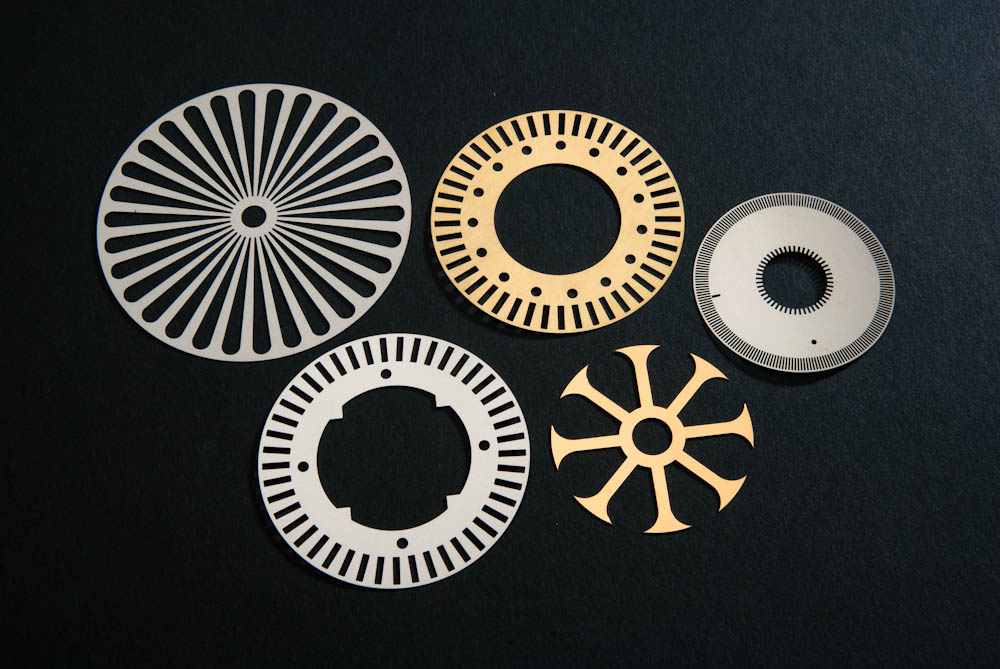

Photochemical Machining (PCM)

Photochemical machining differs from traditional etching methods and is the preferred technique for applications requiring extremely fine features, high part complexity, and zero mechanical stress. The process includes:

- Manufacturers begin by printing the desired product shape on photographic film.

- A metal sheet is cut to size, coated with photoresist, sandwiched between two films, and vacuum-sealed.

- UV light exposure hardens the photoresist in the desired pattern.

- Excess photoresist is washed away, leaving only the areas to be etched exposed.

- An etchant is applied to dissolve the exposed metal, creating the final part geometry.

- After etching, the metal is neutralized and cleaned for downstream processing or assembly.

PCM is widely used for manufacturing precision screens, EMI/RFI shielding, micro-springs, and fuel cell components.

Laser Etching

Laser etching, or laser engraving, utilizes a high-powered laser beam to remove material from metal surfaces. This method is favored for its ability to create precise, clean lines with minimal need for additional finishing. It is particularly popular in the jewelry industry for personalization, as well as in automotive and aerospace manufacturing for durable part marking, barcodes, and serial numbers.

Wet Etching

Wet etching uses a liquid etchant to remove metal:

- Maskant is applied to the metal surface to define the pattern.

- Liquid etchant is applied, which bonds with and removes the exposed metal.

- The reaction between the etchant and metal dissolves the material, typically through a reduction-oxidation process.

- By-products are dispersed and the part is rinsed and dried.

This technique is often used for large-area processing and in the manufacture of printed circuit boards, decorative plaques, and metal mesh.

Dry Etching

Dry etching substitutes liquid etchants with gas or plasma:

- Physical Dry Etching: Utilizes kinetic energy from ions, electrons, or photons to etch metal without chemical reactions. This is common in semiconductor device fabrication and micro-machining.

- Chemical Dry Etching: Relies on chemical reactions induced by gases like chlorine, fluorine, or nitrogen trifluoride for vapor phase etching. This process enables ultra-fine patterning and is often used in the production of microelectronic devices and MEMS.

Electro Discharge Machining (EDM)

Electro discharge machining achieves high precision by subjecting metal parts to controlled electromagnetic discharges, removing imperfections like burrs and marks after processing. EDM is indispensable for producing complex dies, molds, and components with tight tolerances, especially in the aerospace and medical sectors.

Benefits of Metal Etching

Metal etching offers numerous advantages, regardless of the chosen method. It is highly versatile, suitable for a wide range of metals and alloys, and can also be applied to soft plastics and certain types of glass. This process is unique in that it does not induce internal stress, deformation, or waste material, making imperfections very rare. Consequently, it typically requires minimal to no secondary tooling. Additionally, metal etching eliminates the need for hard tooling, allowing manufacturers to execute it quickly and precisely while easily making design adjustments if necessary. Furthermore, metal etching does not affect the material properties. Key benefits include:

- High precision and repeatability for micro- and macro-scale applications

- No mechanical or thermal stress for delicate or thin-gauge materials

- Rapid prototyping and fast turnaround for custom designs

- Cost-effective for both small and large production runs

- Excellent for complex, intricate, or high-density patterns

- Minimal burrs or post-processing, saving time and cost

- Environmentally friendly options available with modern etchants and recycling processes

Common Use Cases and Applications

Wondering how metal etching can solve your manufacturing or design challenges? Here are some of the most popular use cases:

- Printed Circuit Boards (PCBs): Essential for modern electronics, metal etching enables the production of complex circuit layouts with fine tolerances and high signal integrity.

- Medical Devices: Stents, surgical instruments, and implantable components benefit from burr-free, precise features that support patient safety and regulatory compliance.

- Aerospace Components: Lightweight, high-strength parts such as filters, heat exchangers, and airframe components are made possible with chemical milling and photochemical machining.

- Automotive Industry: Etched badges, dials, filters, and decorative trim pieces combine durability and customization for top-tier vehicles.

- RF and EMI Shielding: Thin, precisely patterned metal screens provide electromagnetic interference protection for sensitive electronics.

- Consumer Electronics: Nameplates, logo badges, and speaker grilles are produced with detailed branding and aesthetic appeal using etching.

- Architectural and Decorative Panels: Custom signage, elevator doors, and wall panels feature intricate designs that are durable and easy to maintain.

- Industrial Filtration: Precision-etched screens and meshes are used in food processing, pharmaceutical, and chemical industries for high-performance filtration.

Buyer Considerations: How to Choose a Metal Etching Company

Before consulting with a metal etching manufacturer, it’s important to prepare a detailed list of your specifications. Consider factors such as your requested volume, the level of design precision you need, the depth of cuts required, industry standards, budget, timeline, and delivery needs. Having a clear understanding of your requirements will help you and the service provider determine if you’re a good fit for each other.

Are you looking for high-volume production, or do you need rapid prototyping for a new product? Do you require specialized materials or compliance with strict industry certifications? These are critical questions to ask during your search for the ideal metal etching partner.

Once your list is ready, explore the quality metal etching companies we’ve compiled on this page. This curated list saves you from the overwhelming information often found in Google search results. While all the companies listed are reputable, not every one will be the right fit for your specific needs. The ideal manufacturer will align best with your requirements, offering the right capabilities, capacity, and experience.

To find the right match, browse through the company profiles. Select three or four that seem most suitable and reach out to them to discuss your specifications. After your conversations, compare and contrast the information gathered to choose the manufacturer that best meets your needs.

Frequently Asked Questions About Metal Etching

- What is the difference between chemical etching and laser etching? Chemical etching uses liquid or gas etchants to remove material selectively, while laser etching employs a focused laser beam for direct material removal. Chemical etching is better for high-volume, intricate parts, while laser etching excels in personalization and rapid marking.

- Which metals are best suited for precision etching? Stainless steel, copper, nickel, aluminum, and brass are all excellent choices due to their etchability, mechanical properties, and suitability for a wide range of applications.

- How accurate is modern metal etching? Photochemical and chemical etching can achieve tolerances as tight as ±0.01mm, making them ideal for micro-components, precision filters, and electronic parts.

- What industries benefit most from metal etching? Aerospace, defense, medical, electronics, automotive, and consumer goods manufacturers all benefit from the flexibility, speed, and precision of modern etching processes.

- Is metal etching environmentally friendly? Many companies now use recyclable etchants and closed-loop waste management systems, making modern etching processes safer and more sustainable than ever.

- How can I get a quote or sample for my project? Use our directory to contact leading metal etching companies and request a quote or sample based on your part drawings, material needs, and production volume.

Take the Next Step in Your Metal Etching Project

Ready to bring your design to life with precision metal etching? Whether you are an engineer seeking custom metal photo etching for electronic components, a designer in need of decorative etched panels, or a manufacturer looking to streamline medical device production, our network connects you with industry-leading suppliers offering a full spectrum of metal etching services.

Not sure which process or material is right for your application? Ask a metal etching specialist about:

- Material selection and compatibility for your project

- Choosing between chemical, photochemical, or laser etching

- Surface finishing options for enhanced durability or appearance

- Compliance with standards such as ISO 9001, AS9100, or ISO 13485

- Cost-saving strategies for prototyping and large-scale production

Explore our comprehensive resources and compare metal etching companies to request quotes, samples, or technical advice. With the right partner, you can achieve outstanding quality, fast turnaround, and cost-effective production for any metal etching application.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services