The process of photochemical machining starts by creating a phototool. The phototool consists of two sheets of photographic film on which the negative images of the desired parts are printed. Once the phototool has been designed and printed, metal sheets are prepared for the etching process. Read More…

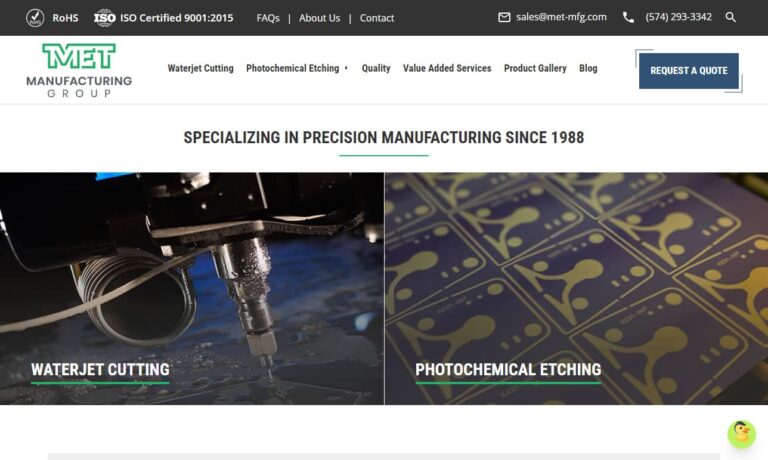

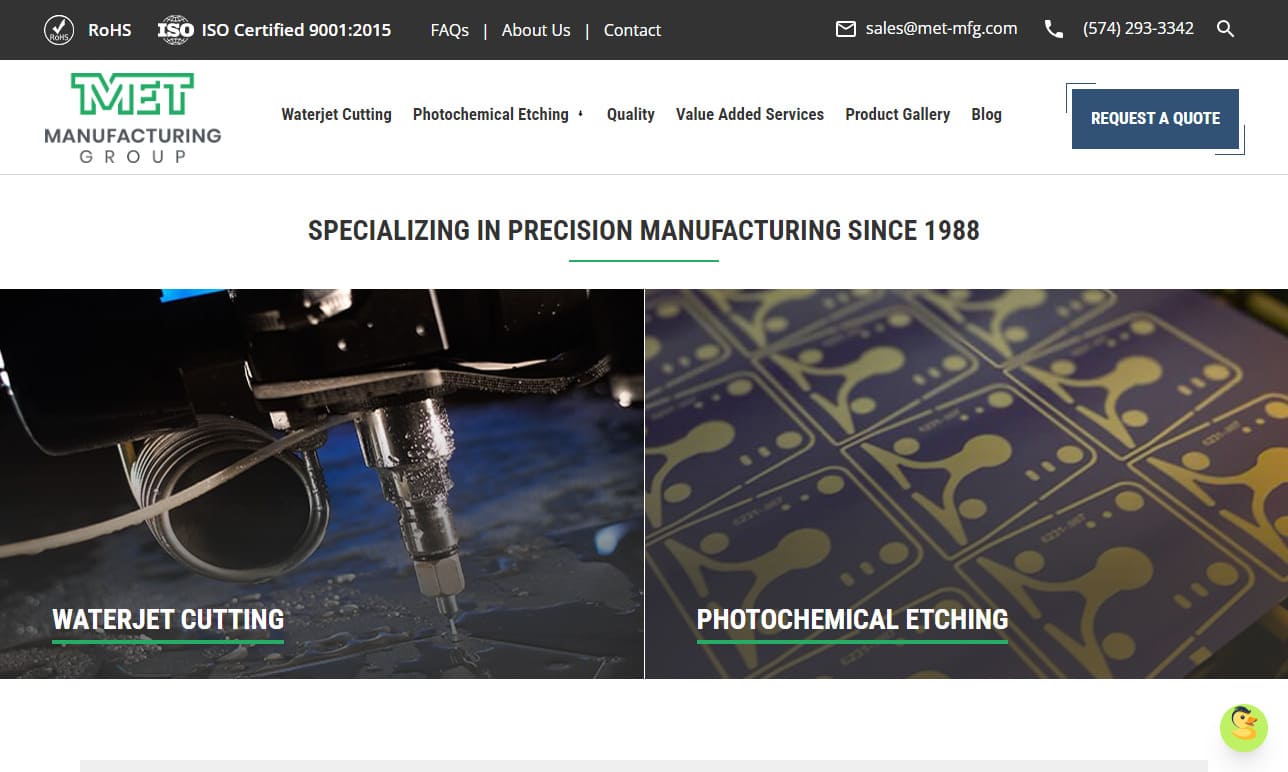

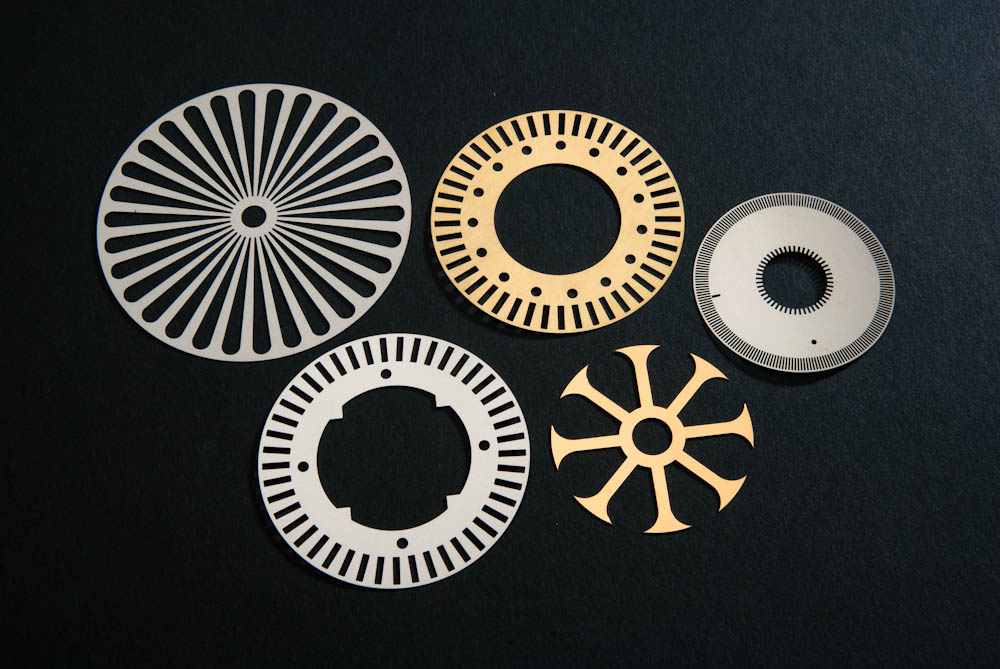

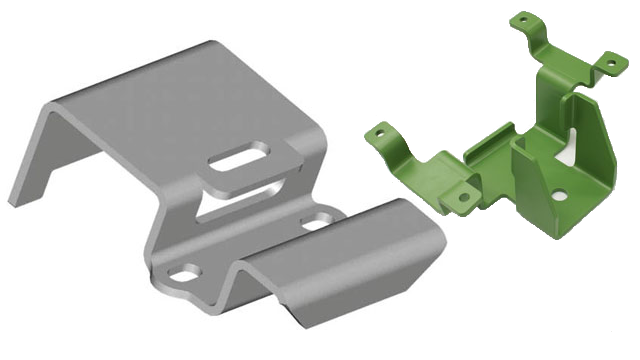

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

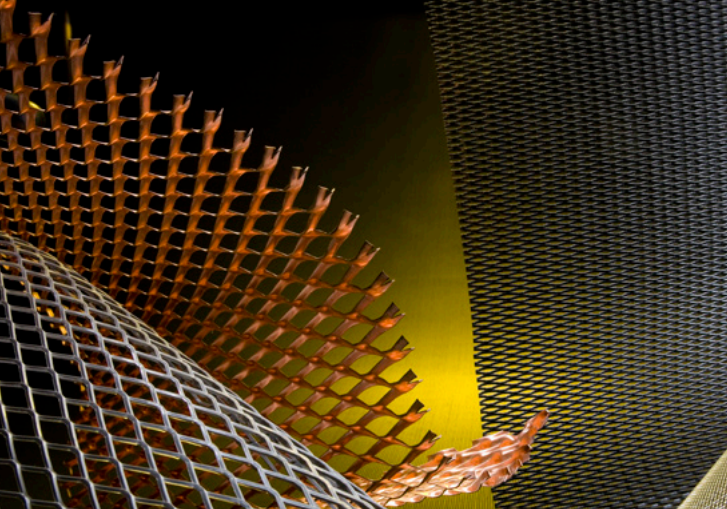

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

More Photochemical Machining Companies

The sheet metal must be cleaned thoroughly and laminated on both sides with a photo sensitive film called a photoresist. The metal can be laminated using the roller method or the wet dip method. The roller method requires the sheet metal to pass through rollers which apply laminate to both sides, while the wet dip method involves dipping the metal into a liquid film and then baking the sheet to harden the film.

After lamination, the metal is placed between the two halves of the phototool and exposed to high intensity UV light which transfers the image from the phototool onto the laminated surface of the metal. Exposure to UV light hardens the exposed film. The metal must then undergo a developing process. The photoresist developer washes away the unhardened film leaving the areas to be etched exposed to the etching agent.

Then the metal sheet is placed on a conveyor which passes through the etching machine which contains a series of spray nozzles above and below the conveyor. As the metal sheet travels through the machine, the nozzles spray a heated, acidic solution onto both sides of the sheet metal.

When the acid comes in contact with the unprotected metal it quickly corrodes the metal away, leaving only the laminated sections intact. All that remains are the desired parts. These parts are rinsed, and the remaining lamination is removed.

Photo chemical etching offers many distinct benefits and advantages as a metal etching process. Possibly one of the most advantageous attributes of this process is its cost effectiveness. Compared with other etching and machining processes, phototooling costs are incredibly low, and phototools take substantially less time to create.

Photo etching is also an excellent option for prototyping since costs are so low and tooling is so quickly created and changed. Unlike machining tools, phototools are only exposed to light which drastically reduces wear and damage to the tool, which then drastically reduces tool repair and maintenance costs. Since there is no mechanical cutting, the process does not create sharp edges, and it does not alter the physical properties of the metal.

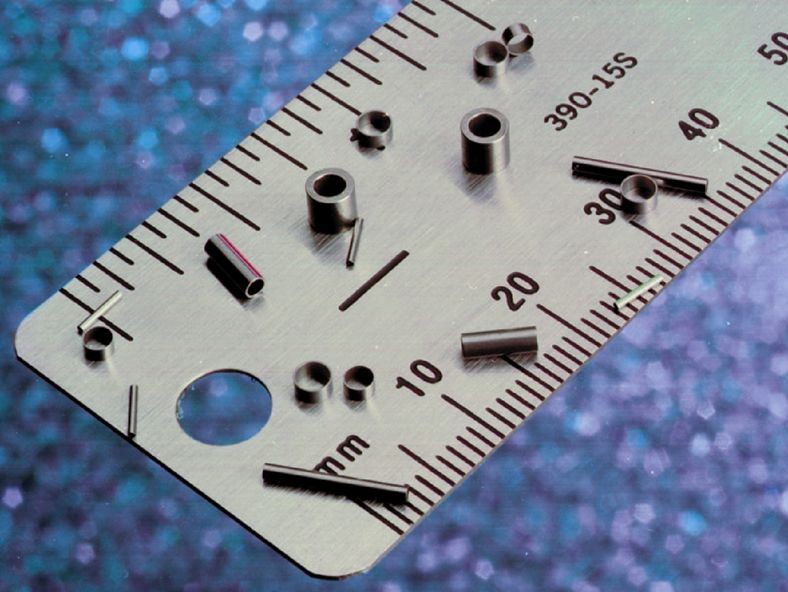

Essentially any metal or alloy can be used in this process, and it can be used effectively on materials with thicknesses between 0.0005 and 0.080 inches. For these reasons, photo etching is often used in creating precision components in the electronics and hardware industries.

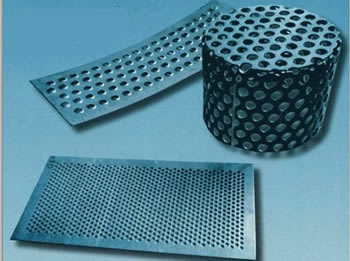

Products commonly created using photochemical machining include: fuel cell components, sensors, metal gaskets, shields, washers, and more.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services