There are two types of metal engraving tools: mechanical and manual. The burin, flat engraver, angle tilt tool, and Florentine liner are manual metal engraving tools. Heavy-duty projects typically require mechanical equipment, whereas specialists may need specialized tools. The type of metal being engraved, the nature of the project, the needed output levels, and other factors all play a role in choosing the best metal engraving tools. Read More…

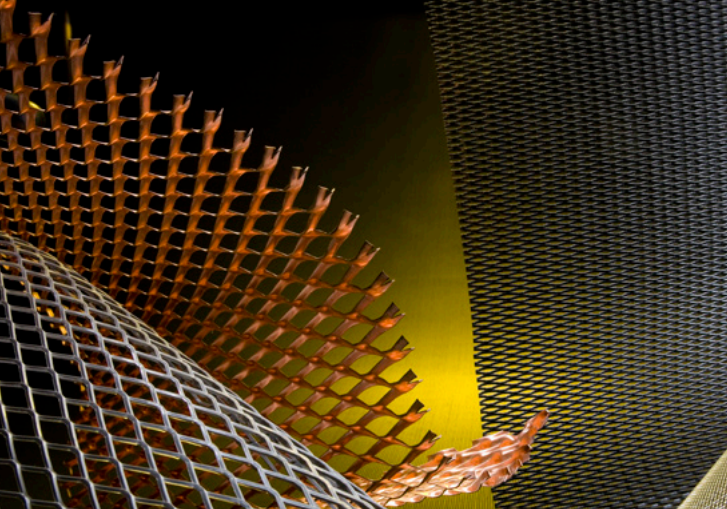

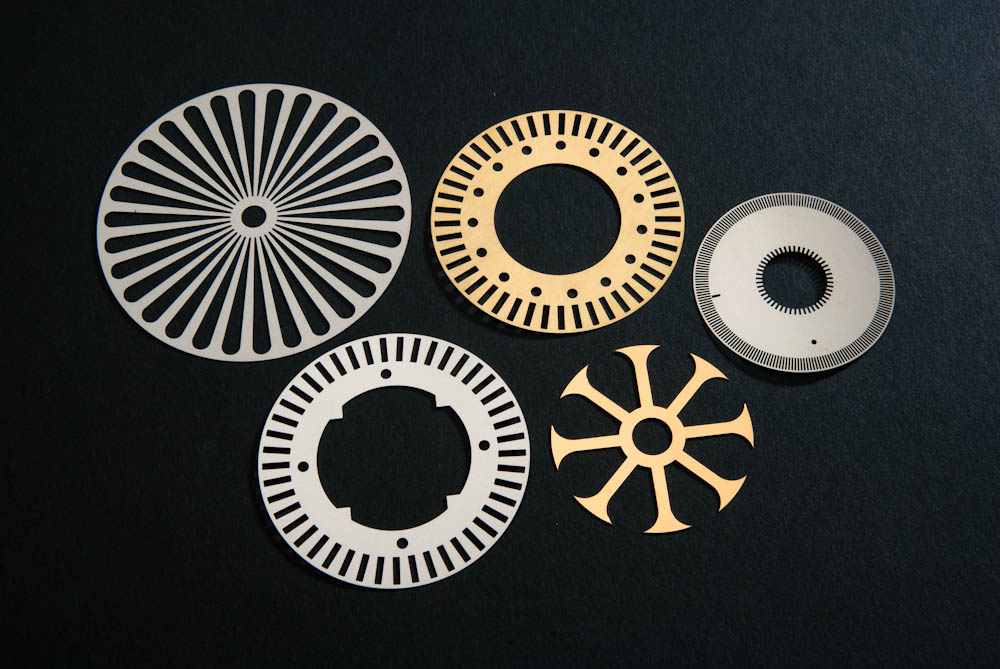

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

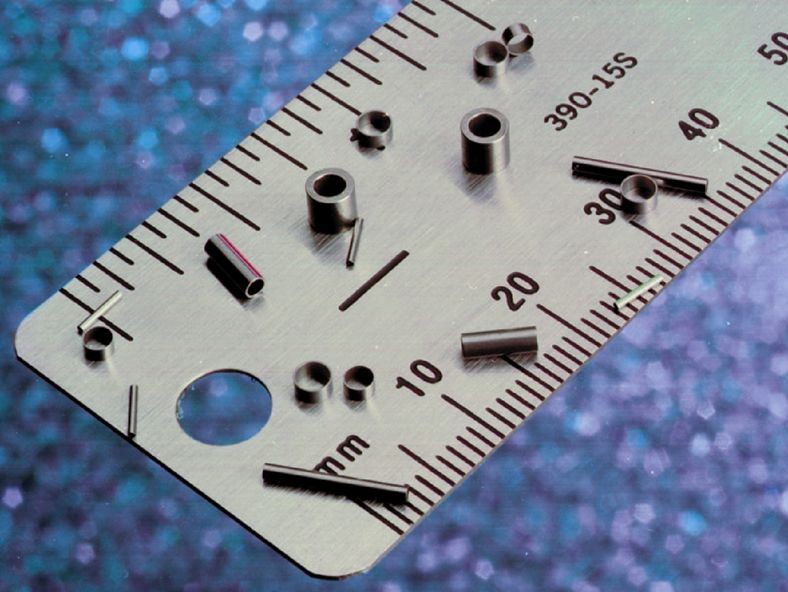

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

More Metal Engraving Companies

Since its shape allows for creating crisp edges while engraving various patterns, the burin is the most frequently used tool. A fine edge is provided by flat engravers, enabling the fabrication of parallel patterns, block letters, and complex backgrounds. The curled tip of angle tilt engravers makes them ideal for designs with curling lines or ribbon motifs. Finally, Florentine lining tools can engrave vast regions at once since the tool's tip has several lines.

Industrial metal engraving machines are frequently employed in industries requiring quick turnaround and high productivity. Diamond tips are offered for machines that cut more precisely and maintain their sharpness for longer. The only way to engrave some metals, like titanium, is with a machine. The titanium material must be light to operate the machine, and lubricant is required to prevent bursts. Since it can be challenging to block complicated designs while engraving with a machine, this can restrict the engraver's creative capacity.

When choosing a tool for a project, the substance of the metal engraving tool is crucial since it needs to be stronger than the metal being engraved. For instance, while steel engraving must be properly hardened, carbon steel tools are frequently used for engraving sterling gold and silver. In addition, the material used for the tool should be simple to sharpen and maintain because a dull blade might make etching challenging or impossible. For instance, sharpening instruments made of carbon steel is easier than those made of steel.

Different widths and forms of metal engraving tools are available to provide engravers better flexibility and reduce the time needed to complete larger jobs or intricate designs. For example, using a tool with a round, flat, or square shape can make it easier to engrave specific shapes or shade backgrounds. In addition, Western lettering engravers might discover that larger, angled metal engraving tools simplify the process.

Metal Engraving Methods

Most engraving shops use the following procedures as standard operating procedures.

Diamond-Drag Scratch Engraving

A non-rotating tool with a diamond tip in the shape of a cone is used in this technique. The metal component receives an impression after being passed through by the engraving tool. Diamond-drag engraving is as exact and high-quality as hand engraving. The stroke's depth does not change while its width remains constant. Diamond drag is suggested for engraving jewelry and awards on soft metals. This technique has the advantages of being generally the quickest, least expensive, and allowing for small engraved letters due to the width of the stroke. However, the fact that the stroke width is constrained is negative.

Burnishing

A revolving tool with little pressure is used for burnishing. The tool removes the top coating or layer of material and leaves behind a smooth, polished finish; it is either a carbide or a diamond cutter with various tip widths. Diamond drag can be substituted with burnishing in some circumstances. However, for many shops, burnishing is still a relatively new technique. The almost limitless stroke width and increased letter heights that can be attained with burnishing are advantages. However, it is more expensive and requires a loud engraving engine and a burnishing adapter.

Rotary Engraving

This technique removes material from metal components using a single or multiple-fluted cutting tool, leaving a trough where the exposed core resides. It causes a letter or item to be completely chopped off or get a deeper cut. The spindle micrometer setting determines the cut depth in the majority of applications. Therefore, most commercial and industrial workers may be using this method.

The most durable type of engraving, rotary engraving, can produce two- and three-dimensional appearances and can produce letters of almost any size. However, some disadvantages include the need for a larger variety of cutting tools, a rotary spindle, and a motor, as well as the fact that additional cleanup is usually necessary.

Laser Beam Engraving

A laser engraver can cut, engrave, or mark metal items. The surface of the metal is physically removed by the laser beam, resulting in a chamber that houses an at-eye-level image. In addition, high heat is generated by the laser beam during the operation, effectively causing the material to evaporate.

The advantages of laser engraving include its speed, affordability compared to CNC equipment, and lack of waste such as sawdust. Its high precision and quality also enable more intricate graphics and cleaner cuts. However, thick materials are more difficult to cut with a laser or need extremely slow speeds. Furthermore, the laser burns the edges of any material being cut, which is a negative. In addition, the production cost can rise because of the high energy consumption of laser engraving equipment.

Engraved Metals

Each metal has strengths, weaknesses, and ideal applications depending on its constituent elements and different techniques best suited for different metals.

Aluminum

Plaques and trophy plates are made of aluminum that has been brightly coated or anodized. Control panels, interior and exterior signage, and industrial applications are all made with machining-grade aluminum. Compared to brass, copper, and bronze, this metal surface might be unpredictable in terms of cutting difficulty. The majority of aluminum alloys, though, can be cut with enough practice and persistence.

Brass

Brass that is bought in stores is challenging to engrave. The much softer "engravers’ brass" or "half-hard" brass is available from producers of engraving supplies. Brass with a thickness of.040-.060 in. is suggested for deep-cut signs. This metal can be painted to contrast the lettering and the brass background. Brass is a metal alloy frequently marked because laser etching leaves a strong black mark on it.

Stainless Steel

Stainless steel has many advantages but is more difficult to engrave. It is long-lasting, impervious to moisture and corrosion, and doesn't contaminate other materials. It is utilized in hospitals and food processing facilities where most metals are destroyed by corrosion or reactivity. Containers, control panels, switch and legend plates, signage, and elevator panels are some of their many uses.

A collet spindle is one of the most crucial instruments when cutting stainless steel. The split collet on the collet spindle captures the cutting tool variation close to the work area. This added stiffness will enable deeper cuts with less chipping or breakage of the cutter. In addition, steel cannot be laser engraved because the heat from the laser eliminates a crucial protective layer; however steel can be laser annealed.

Gold, Silver, Pewter

These metals are pliable and simple to cut. Most engraving applications, including jewelry customization, work well for them, and the preferred technique is diamond drag engraving. It is simple to cut these materials deep using the same cutting tools for brass. Most of the time, cutting fluids are not required.

Choosing the Proper Metal Engraving Company

To make sure you have the most positive outcome when purchasing Metal Engraving from a Metal Engraving Supplier, it is important to compare at least 5 or 6 Companies using our list of Metal Engraving suppliers. Each Metal Engraving Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Metal Engraving business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Metal Engraving businesses with the same message.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

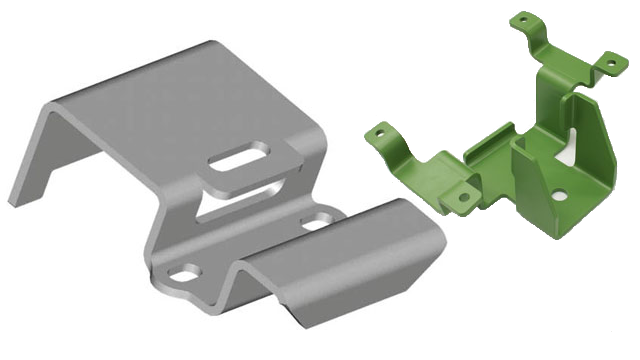

Metal Etching Metal Fabrication

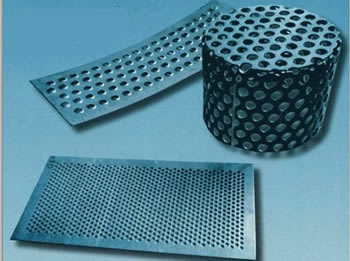

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

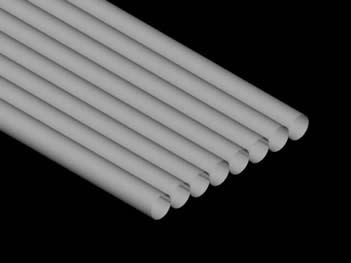

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services