With chemical etching, it is possible to permanently etch an image into metal by removing material with a high-pressure, high-temperature chemical spray. The metal is then exposed to produce the desired image after a mask or resist has been put to the material’s surface. Read More…

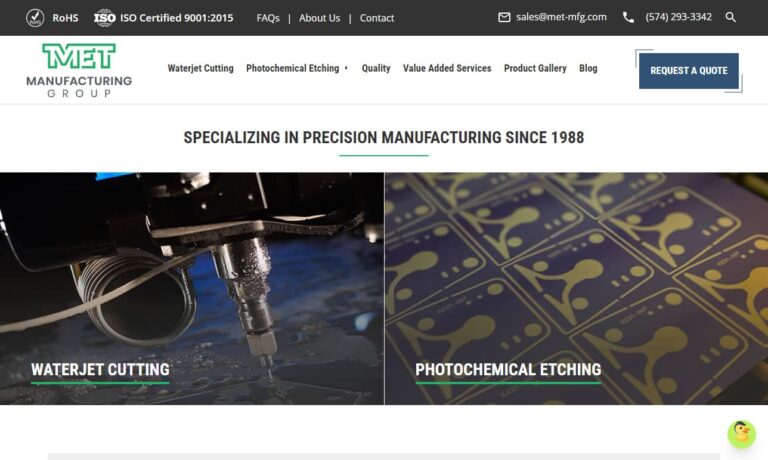

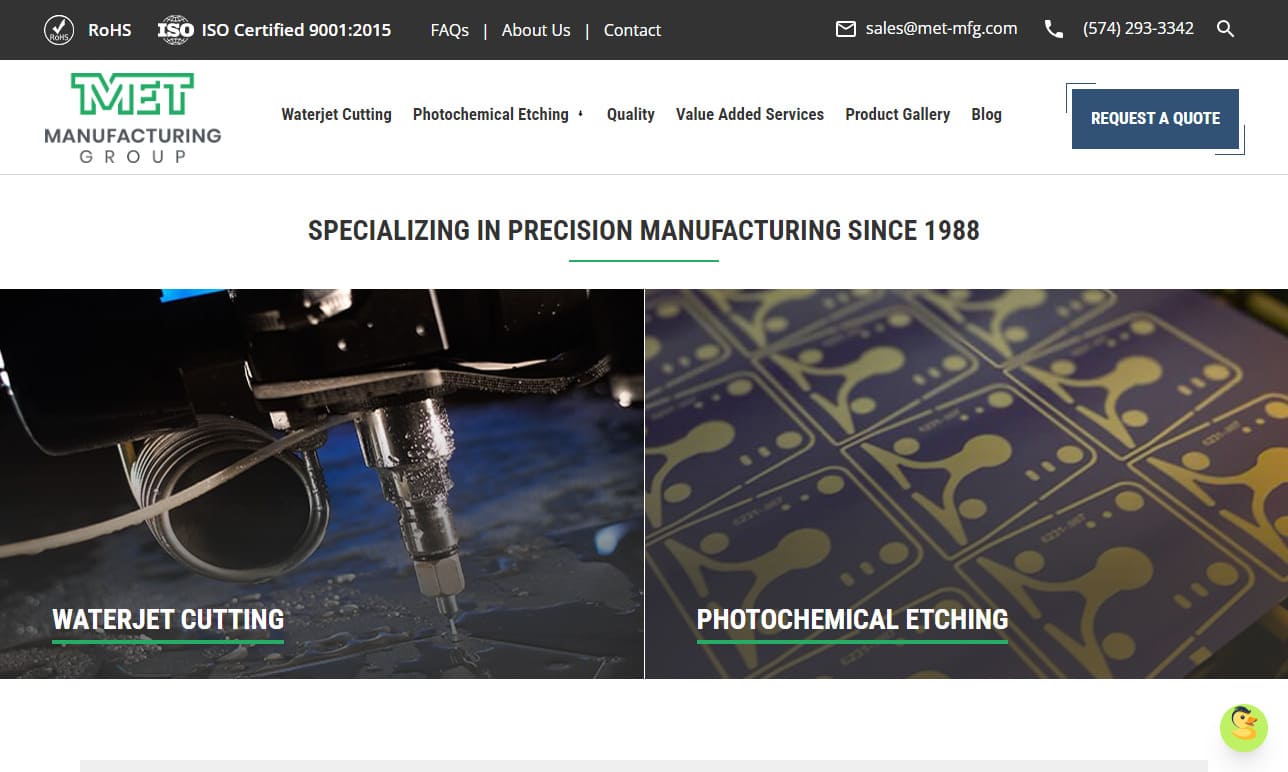

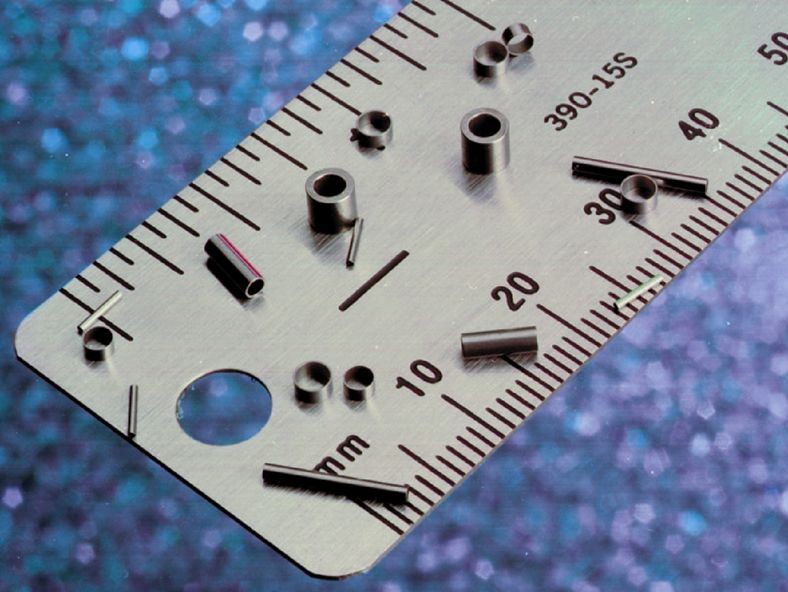

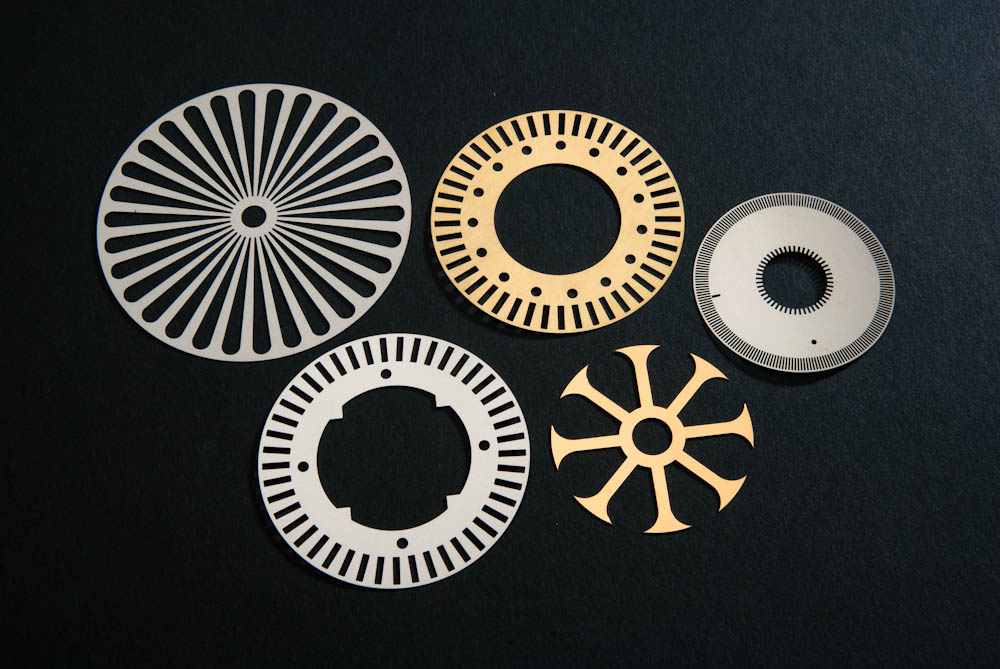

The MET Manufacturing Group, LLC process offers many technical & financial advantages in manufacturing various flat metal components. Try this precision etching, non-mechanical process for competitively priced, burr & stress free sheet metal products, up to 62 mil (.062”) thick. Our photo-chemical machining process is also known as photo-fabrication, photo etching, chemical milling & acid...

Etchit is your high-quality solution for custom-manufactured precision metal parts and components. We use photochemical machining to make products for such industries as aerospace, audio, automotive, computer, circuit board, decorative and fastener. Does your product need photo etching processes?

VACCO is the industry leader of Photo Chemical Etching of metal & polyimide components and devices. We specialize in Stainless steel, Titanium, and Copper, but work with a variety of different materials. We have over 60 years of experience in Chem Etching, and we offer Micro Laser Cutting & Welding, and Diffusion & Adhesive Bonding services along with an extensive range of value-added services. ...

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Titanium, Nitinol, Nickel, Kovar and many others.

More Chemical Etching Companies

An etching machine accelerates the corrosive chemical reaction between the chemical and the material by heating the solution and spraying it at high pressure. The chemical spray dissolves the exposed metal regions, atom by atom, etching the substance for a flawless, burr-free surface.

Chemical Etching Working Principle

Traditional chemical etching involves several procedures, including:

Cleaning: In this stage, impurities such as grease, oils, and residues are removed from the metal surface in preparation for the etching process. Cleaning is crucial since a polluted surface may cause the photoresist coating to adhere poorly, leading to faults. Additionally, employees should never handle the material with bare hands after finishing this process because human sweat and oils may contaminate it.

Lamination: In lamination, dry film photoresist is applied to the surface. The parts of the metal that won't be etched are shielded by a photoresist. These films are rolled or laminated onto the material while being simultaneously applied to both sides utilizing pressure, temperature, and occasionally water.

Exposure: During exposure, the material is moved between two "masks" that each depict the final component negatively. Either glass or mylar is used to make these masks. The film is then crosslinked in areas where the mask images do not obstruct the light by shining high-intensity, collimated ultraviolet light through the masks in both directions.

Developing: The material needs to be developed after exposure. The non-crosslinked film is chemically removed in this stage, revealing the bare metal underneath. The final output will be the stuff that the film has shielded.

Etching: The metal is fed into etching chambers after developing, where the etchant is simultaneously sprayed from the top and bottom. The exposed metal is etched or dissolved during this procedure to provide the desired result. Monitoring the concentration, composition, temperature, and time of an etchant bath is crucial.

Stripping: In this procedure, a different chemical concentration is used to remove the film from the etched product.

Rinsing and Drying: At this point, the product is finished, and the films are taken off. All residuals must be thoroughly removed by rinsing. Most likely, reverse osmosis and deionized water are used to do this.

Materials Suitable for Chemical Etching

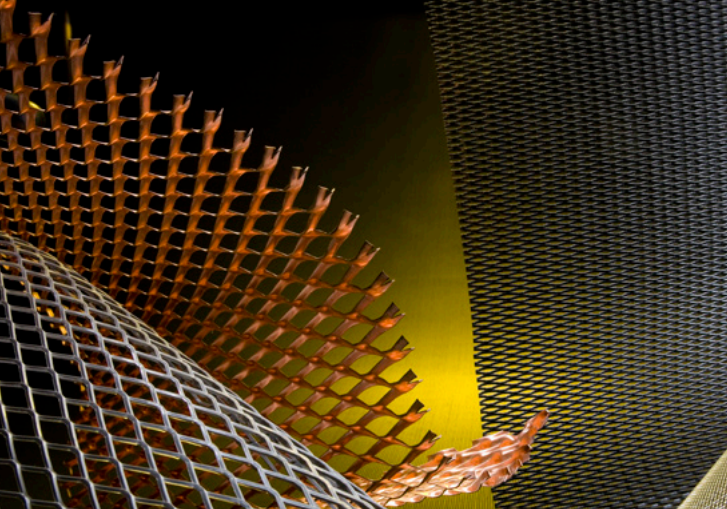

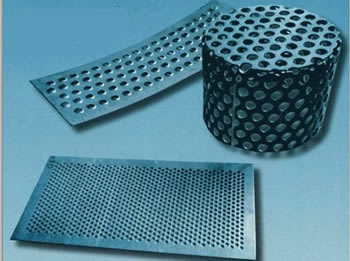

Stainless steel sheets, nickel alloys, copper, brass, beryllium copper, and phosphor bronze are among the numerous metals that can be chemically etched.

Reel-to-reel Etching

The chemical etching procedure has seen numerous improvements, enabling reel-to-reel production, vertical integration, higher tolerances and reproducibility, and shortened time-to-market. These developments have made it possible to undertake half-etching methods for more challenging and specialized applications, such as hand break-offs, capillary grooves, and other complicated features with sharp beveled tips and edges. Additionally, Interplex uses a fully computerized process control system to guarantee high product quality, homogeneity, consistency, and reproducibility.

Advantages of Reel-to-Reel Etching

A closely controlled reel-to-reel etching process is essential to keep precise tolerances, a high level of reproducibility, and high production output. In addition, reel-to-reel etching, as opposed to panel etching, is naturally automation friendly and enables the seamless integration of subsequent processing stages. For instance, utilizing various automated tools, the etched metal components can be produced, plated, or inserted and molded.

Additional benefits include:

- Reel-to-reel etching exhibits excellent reproducibility and consistency while maintaining extremely tight tolerances for small feature sizes.

- The total cost for quality is greatly reduced by improved consistency and repeatability, especially in high-reliability applications.

- Traditional metal stamping techniques cannot produce precision metal components with no burrs, ultra-fine pitches, complicated forms, or 3D feature profiles.

- High-volume manufacture of chemically etched parts lowers tooling and production costs while accelerating time to market.

- In order to lower overall manufacturing costs, reel-to-reel etched parts can be used in various automated processes like forming, plating, insert molding, and assembly.

- A continuous chemically etched metal strip that benefits from mass manufacturing are an alternative to the conventional panel or sheet etching technique thanks to the achievable accuracy and uniformity levels. Additionally, the reel-to-reel chemical etching approach's great control and flexibility allow it to design and manufacture parts that essentially fulfill any particular application requirements.

- Chemical etching is a great technique for producing complex, multi-layered metal objects with high precision. It is also the ideal method for producing round holes and edges that are straight, sharp, or contoured.

- It makes it possible to produce complicated and sophisticated metal parts that cannot be made using other production techniques, making it a viable, purposeful alternative to traditional stamping and other manufacturing procedures.

Choosing the Proper Chemical Etching Supplier

To make sure you have the most productive outcome when purchasing Chemical Etching from a Chemical Etching Supplier, it is important to compare at least 4 Manufacturers using our list of Chemical Etching companies. Each Chemical Etching Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Chemical Etching business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Chemical Etching companies with the same message.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

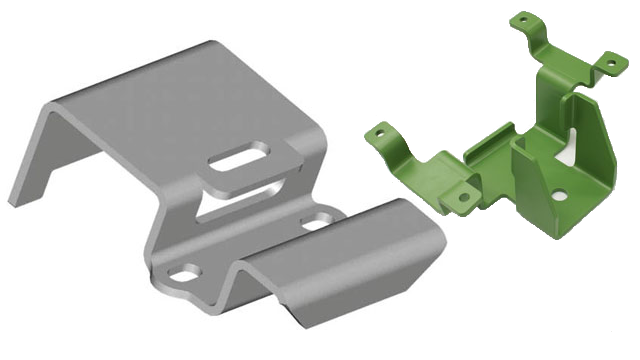

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services