At the most basic level, etching is a process by which certain portions of a work piece are masked by a non-reactive material, and the rest is exposed to a chemical that attacks the exposed areas, dissolving them to the depth required by the work piece design parameters, sometimes to depths of half an inch. The masking material is then removed and the part washed to prevent further etching before the part undergoes further machining.

The challenge is to find the right etching solution for the material you are working with, because different chemicals react to different materials in different ways; some doing little more than revealing the grain and others eating deeply into the surface. For example, steels are generally etched using hydrochloric and nitric acids, with Nital (a mixture of ethanol, methanol, methylated spirits, and nitric acids) being preferred for mild steel and plain carbon steel, and ferric chloride for stainless steel. Aluminum, on the other hand, is etched with either sodium hydroxide, or a mixture of nitric acid, hydrochloric acid, and hydrofluoric acid, called Keller’s Reagent. Like steel, copper can be etched with ferric chloride, and nitric and hydrochloric acids; but it can also be etched using cupric chloride, ammonia, ammonium persulfate, and hydrogen peroxide.

Broaching

Broaching CNC Machining

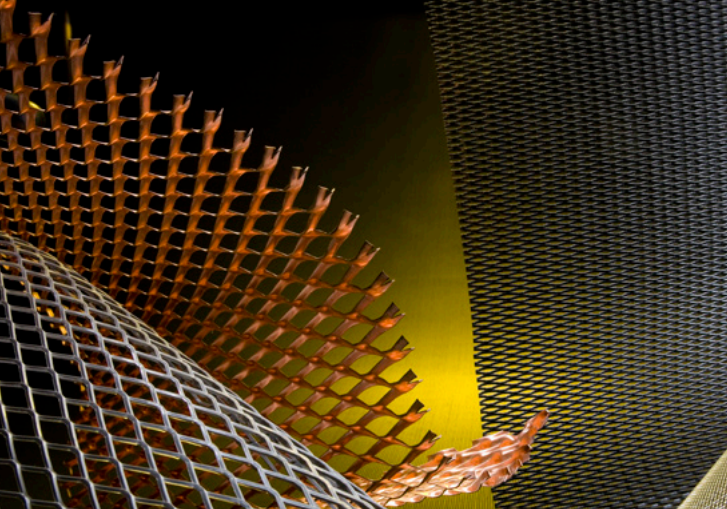

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

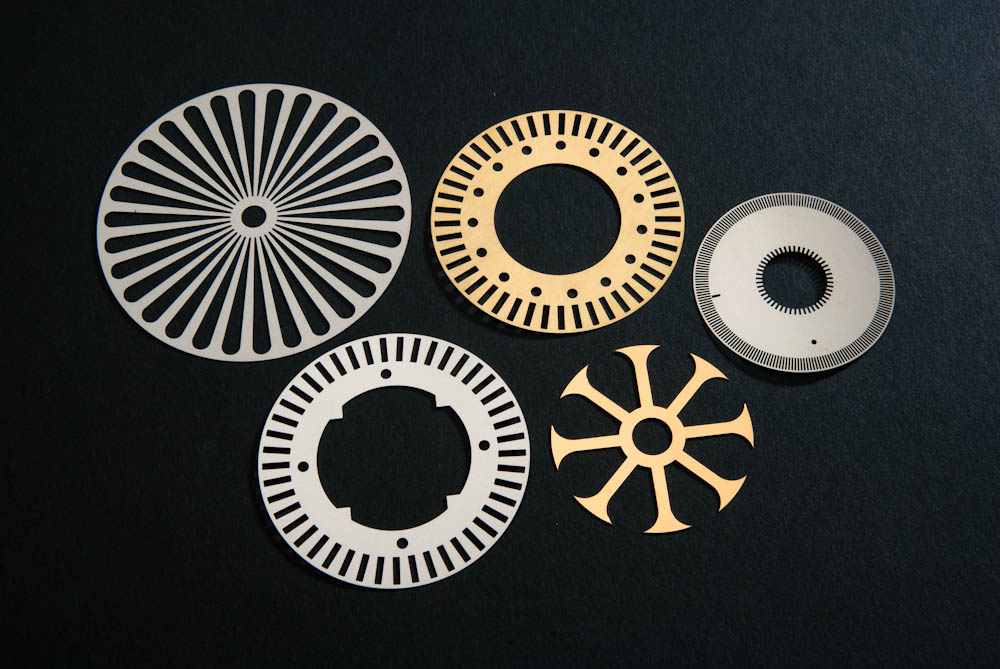

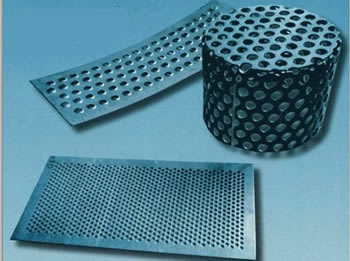

Metal Fabrication Perforated Metals

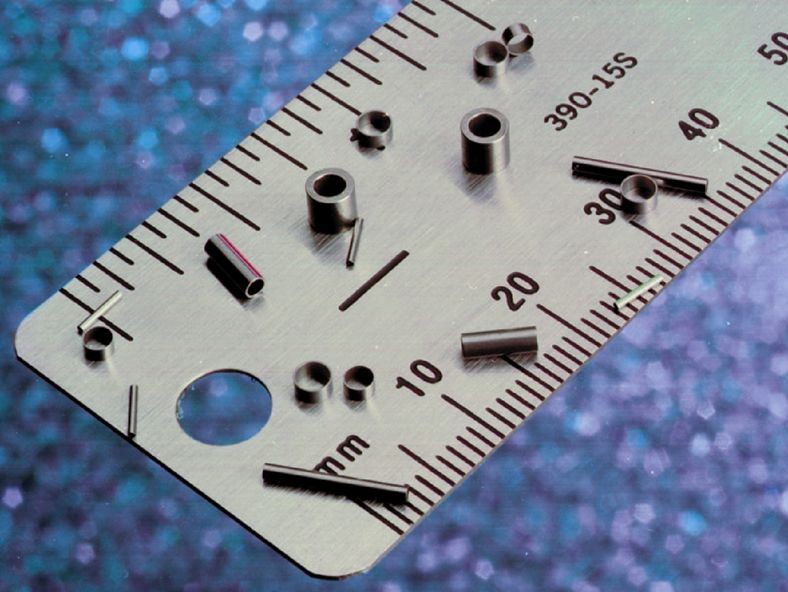

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

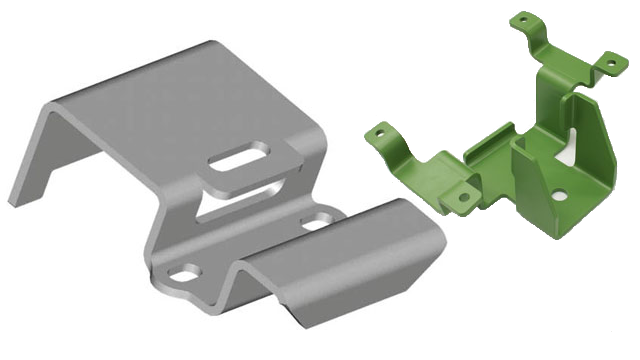

Metal Stampings Sheet Metal Fabrication

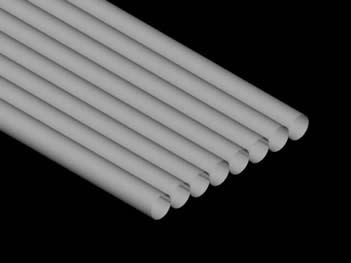

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services